Canister Lid Shields

Dry Cask Canister lid shields provide significant gamma and neutron dose reduction from radiation emitted from the cask. Our shields are custom sized for the specific type of canister they are to be used on. NPO offers two solutions a one-piece canister lid shield and a multi-piece canister lid shield.

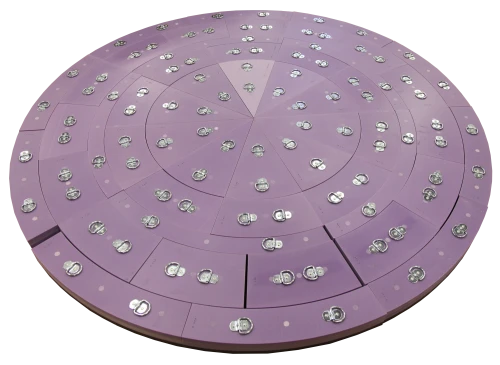

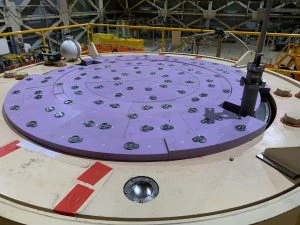

T-Flex® Multi-Piece Canister Lid Shield

Multi-Piece Canister lid shielding allows the site to keep shielding on the canister lid during welding and inspection, while strategically moving and removing a few pieces at a time. A worker can benefit from the majority of the shielding while at the same time having access to specific areas of the canister lid. The lid shield consists of high temperature T-Flex Boron and T-Flex Bismuth. Each piece has integrated stainless steel handles making for easier installation and removal. The weight of each individual piece can be easily carried by one person.

Lid shields can be designed in any configuration with a number of different materials adjusted to meet site dose reduction goals.

T-Flex® and Borated Polyethylene Composite Shielding

This shielding consists of 2” (51 mm) of borated polyethylene plastic, and excellent neutron radiation attenuator, integrated on top of 1” (25 mm) of T-Flex® Tungsten. This shielding system provides about 75% dose deduction from neutron radiation as well as a significant amount of dose reduction from gamma sources. Pieces are modular, weigh less than 40 lb (18 kg) each, and are split per the specifications from the canister manufacturer.

Designed for Specific Applications

The conditions surrounding the canister and operations taking place varies from plant to plant, and not every situation can be easily shielded with a multi-piece full lid shielding package. Temperature, weld operations, space restrictions, and attenuation goals all play a factor in the design of canister lid shielding.

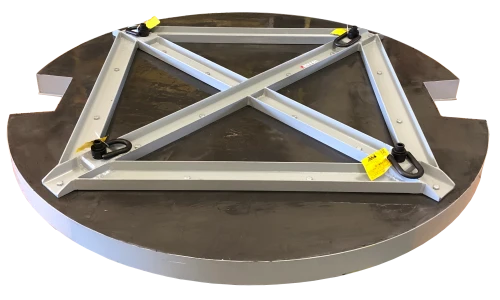

One-Piece Canister Lid Shield

This one-piece canister lid shield consists of 1” of T-Flex® Tungsten and 2.5” of T-Flex® Boron shielding within a steel frame, providing 64% gamma and 73% neutron attenuation. The shield can withstand +350°F operating temperatures. Removable notch pieces located opposite of one another allow for vent/port access. A high density plastic seating pad at the bottom ensures there is no steel-to-steel contact with canister lid. The entire shield is removed during welding.

Interested in learning more about our products?

Send us a message via our contact form, and we’ll answer any questions you may have.