Lead Wool Blankets

Lead Wool Blankets Overview

NPO is the leading manufacturer of lead wool blankets in the world, made in Illinois since 1976.

Lead wool blankets are the industry standard radiation shield product for industrial applications. They are typically used to create a barrier between a radiological source and the rad worker. Lead blankets are often hung on scaffold or cables by S-hooks to create a shield wall. They may also be draped over pipes / valves / heat exchangers or placed on the floor to shield sources from below.

Lead wool blankets are created by forming continuous lead wool rope into the desired shape by use of rollers and dies. The form is then sewn, quilted, and cross stitched inside a layer of PVC to create a billet. The billet is RF sealed inside a second layer of PVC, creating waterproof barrier. The excess PVC is trimmed and grommets are installed.

Lead wool blankets are cost effective, durable, and versatile.

PVC Covered Lead Wool Blankets

NPO had workers’ safety and ergonomics in mind when designing our new standard PVC covered lead wool blankets. The new NPO standard PVC covered lead wool blankets feature handles for quicker and easier handling, printing to declare the weight of each lead wool blanket – assuring workers will know how much they are about to lift, along with larger 25mm grommets for simple, speedier installation on racks or scaffolding. This design is one of a kind and will be applied to every NPO manufactured blanket 60 lb (27 kg) or under.

High Temp Lead Wool Blankets

Available in various sizes, shapes and weights, NPO’s silicone coated fiberglass coverings can withstand continuous temperatures of 550+ degrees Fahrenheit (288 degrees Celsius). The high temperature lead wool blankets are typically used in high temperature applications and have been used as permanent shielding in some facilities.

Custom Lead Wool Blankets

Curved Blankets, Magnets, Straps

Custom lead wool blankets can be designed and made with nearly any 2D layout imaginable. Add magnets, Velcro, cutouts, grommets, and cinch straps, and create a blanket truly designed specifically to get the job done.

Nozzle Shielding

NPO has worked with several BWR plants to create bio-door and nozzle shielding. The circular magnetic shielding is designed to fit snuggly around the nozzle. All pieces are made to fit for each plant’s specifications.

Steam Gen Shielding

Custom fit to any plant’s steam generators, these magnetically secured lead wool panels provide shielding between the worker and the side of the steam generator. The magnetism of these blankets allow for quick installation on any carbon steel surface while offering a significant dose reduction.

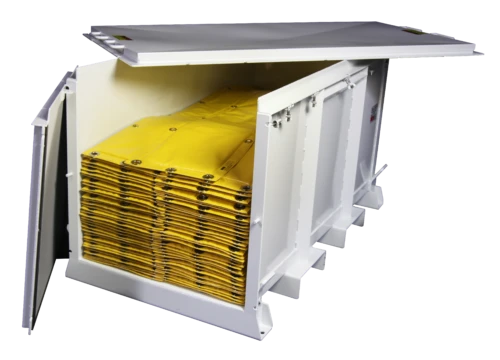

Storage Containers

NPO’s lead blankets are flexible and are manufactured in a multitude of sizes, shapes and weights for effective shielding around components. Standard containers are able to be rigged, moved by fork truck, are weather tight, and feature removable lids and side panels for easy loading and unloading. Project specific shielding such as dry cask or steam generator sludge lancing blankets available upon request.

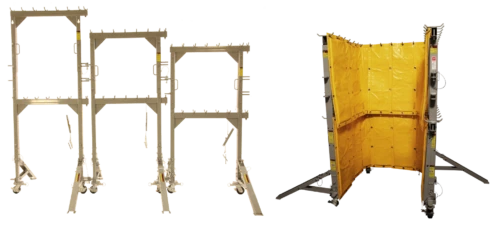

Heavy Duty Support Racks

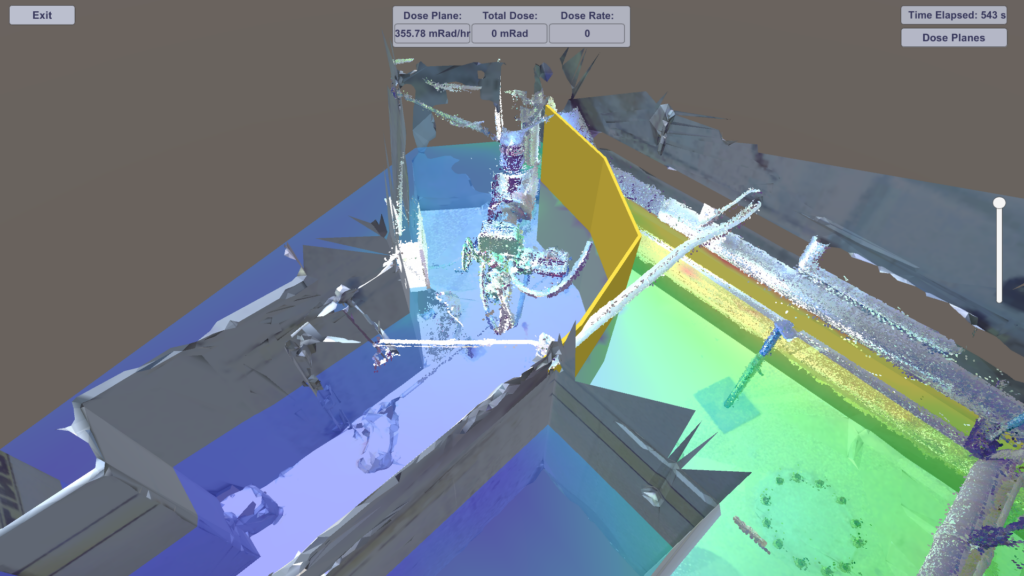

NPO’s serpentine system is designed to provide virtually any shielding wall configuration, including low dose waiting areas, portable frisking caves, shadow shield walls, and shields for rad materials transfers.

This sturdy and adjustable system was designed to replace scaffolding, currently used to hang lead blankets. By placing the installation process in the hands of the RP department, setup time and potentially critical path time is saved.

The serpentine racks are adjustable from 6′ to 8′ (1.83 m to 2.44 m) tall, and link to one another to form a solid, continuous shield wall. Each rack sits on heavy duty casters with foldable steel support legs and is capable of holding 2880 lb (1306 kg) of shielding blankets. Serpentine racks have been seismically qualified.

Light Duty Support Racks

Light Duty racks are an easier to deploy, much lighter weight shielding rack. Each aluminum rack weighs only 45 lb (20 kg), making it light enough to carry by hand and quick to set up. While the frame is aluminum to keep the weigh down, the hooks are carbon steel and are able to handle the wear and tear of repeated shielding blanket install and uninstall.

These racks are ideal for temporary shielding and keeping dose rates low in areas where it would otherwise be difficult to set up a bulky rack or scaffolding system.

The Light Duty racks are 2′ wide and 6′ tall (0.61 m x 1.83 m), and, like the serpentine racks, can link to one another to form a solid, continuous shield wall. Each rack is capable of holding 550 lb (249 kg) of shielding blankets, and have been seismically qualified.

Cargo Net Lattice System

Substitute scaffolding with lattice webbing and integral swivel hooks. These systems are custom manufactured to work with pipes, tanks, or other applications. The integrated hooks cannot be removed and are spaced to fit the grommet spacing of whatever shielding blankets will be used. These are built to order and can be made in virtually any size.

Larger lattice systems may need integrated steel supports. NPO has built cargo net shield walls as big as 18′ x 24′ (5.49 m x 7.32 m).

Hooks and Straps

NPO carries S-Hooks in a variety of standard sizes in both carbon steel and stainless steel. For added security, spring clips can be added to ensure the blanket cannot fall off the S-Hook. Cinch and ratchet straps also in stock to tie together and hold shielding in place.

Custom Shielding Applications

Interested in learning more about our products?

Send us a message via our contact form, and we’ll answer any questions you may have.